Hello everyone, this is Bella from ZHEJIANG WUMA DRIVE CO.,LTD. Next, let me share some professional knowledge about worm gearbox with you.

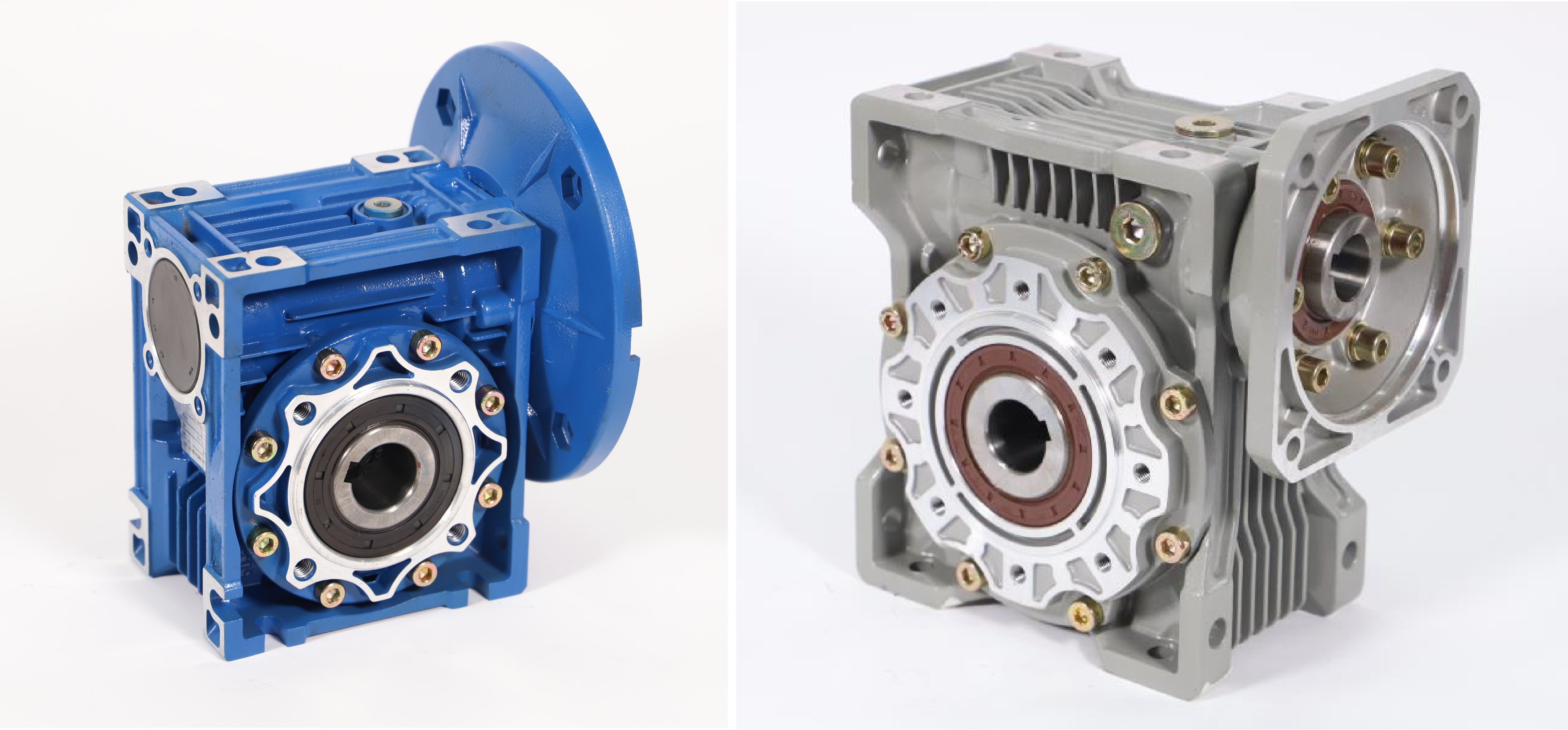

First of all, we know the housing of a worm gear reducer is one of the key parts of the reducer, it will directly affecting the overall performance and service life of the worm gearbox. And the design of the housing not only needs to ensure its functionality, but also needs to showcase the Industrial aesthetics.

The thickness of the worm gearbox housing is also important. When housing is too thin is prone to cracking under stress during operation, which can lead to oil leaks. This will not only cause insufficient lubrication of the internal worm and worm wheel components, but also reduce heat dissipation efficiency, ultimately affecting the performance of the worm gear reducer. Similarly, sand holes in the housing can cause similar problems. Therefore, WUMA has established a rigorous quality control system to ensure that the housing avoids such defects.

Worm gearbox has different materials for housing. For big size models (RV110-185), we use cast iron housings. As we all known, iron rusts very easily, making rust prevention for the cast iron housing of the worm gear reducer extremely important. First, we spray a layer of primer onto the raw material. A good primer prevents the housing from rusting during warehouse storage. At the same time, it is necessary to check the integrity of the housing and see if there are any obvious defects. Finally, we carefully store and inventory these parts to prevent any impact or drop that could damage their structural integrity.

By following these operating procedures, we ensure that the worm gearbox operates at optimal efficiency, providing reliable and long-lasting service.

This year is WUMA 30th anniversary. We are committed to ensuring that every worm gearbox we provide to our customers is 100% qualified and of superior quality, thereby establishing WUMA reputation for quality and durability in the market.

Hot News

Hot News2026-02-24

2026-02-22

2026-02-20

2026-02-18

2026-02-16

2026-02-14