The principle of a reducer

The principle of a reducer refers to the technology of achieving speed matching and torque transmission between a prime mover and a driven machine through a gear transmission device. Its core function is to reduce speed and increase output torque. The main structure includes an input shaft, a driving gear, and a driven gear on the output shaft. Speed reduction is achieved through the difference in the number of teeth; multi-stage meshing can increase the reduction ratio. According to transmission type, speed reducers can be divided into worm reducers, helical gearbox, and planetary gearbox; according to the number of transmission stages, they can be divided into single-stage and multi-stage reducers; according to gear shape, they can be divided into cylindrical gearbox, bevel gearbox, and bevel-cylindrical gearbox; according to the arrangement, they include open-type, split-type, and coaxial structures. Planetary gearbox use a planetary gear, sun gear, and external gear ring structure, and are characterized by small size and high load-bearing capacity .

Types of reducers

The main transmission components are worm gears and worm shafts , with the input and output shafts on different axes, forming a 90-degree angle. Worm gear reducers can achieve large reduction ratios and, under certain conditions, have a reverse self-locking function, preventing reverse rotation. They are easy to install and maintain, but their disadvantages include relatively low transmission efficiency and precision.

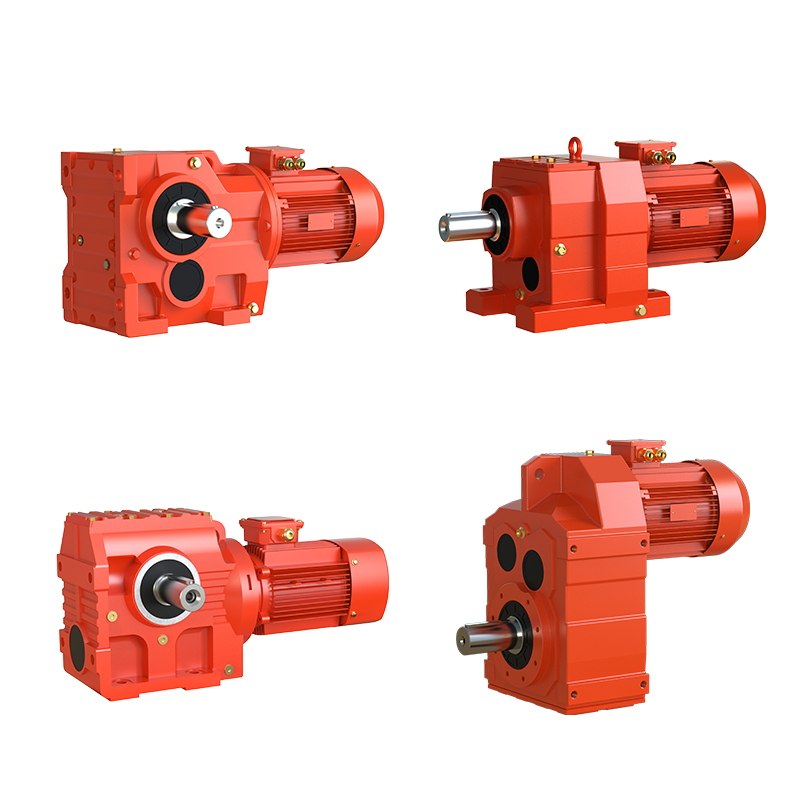

Helical gearbox achieve speed reduction by using gear transmission through multiple stages . A reducer is composed of gear pairs at various stages ; for example, using a small gear to drive a large gear can achieve a certain degree of speed reduction . By employing multiple stages of this structure , the rotational speed can be significantly reduced .

Gear reducers have the following characteristics: 1. Space-saving, reliable and durable, high overload capacity, power up to 132KW ; 2. Low energy consumption, superior performance, reducer efficiency up to 95% ; 3. Low vibration, low noise, high energy saving; 4. Made of high-quality forged steel, with a rigid cast iron housing, and gear surfaces undergo high-frequency heat treatment; 5. Precision machining ensures shaft parallelism and positioning bearing requirements , forming a helical gear transmission assembly. These reducers are compatible with various types of motors. The combination of electromechanical components fully guarantees the quality and characteristics of the product.

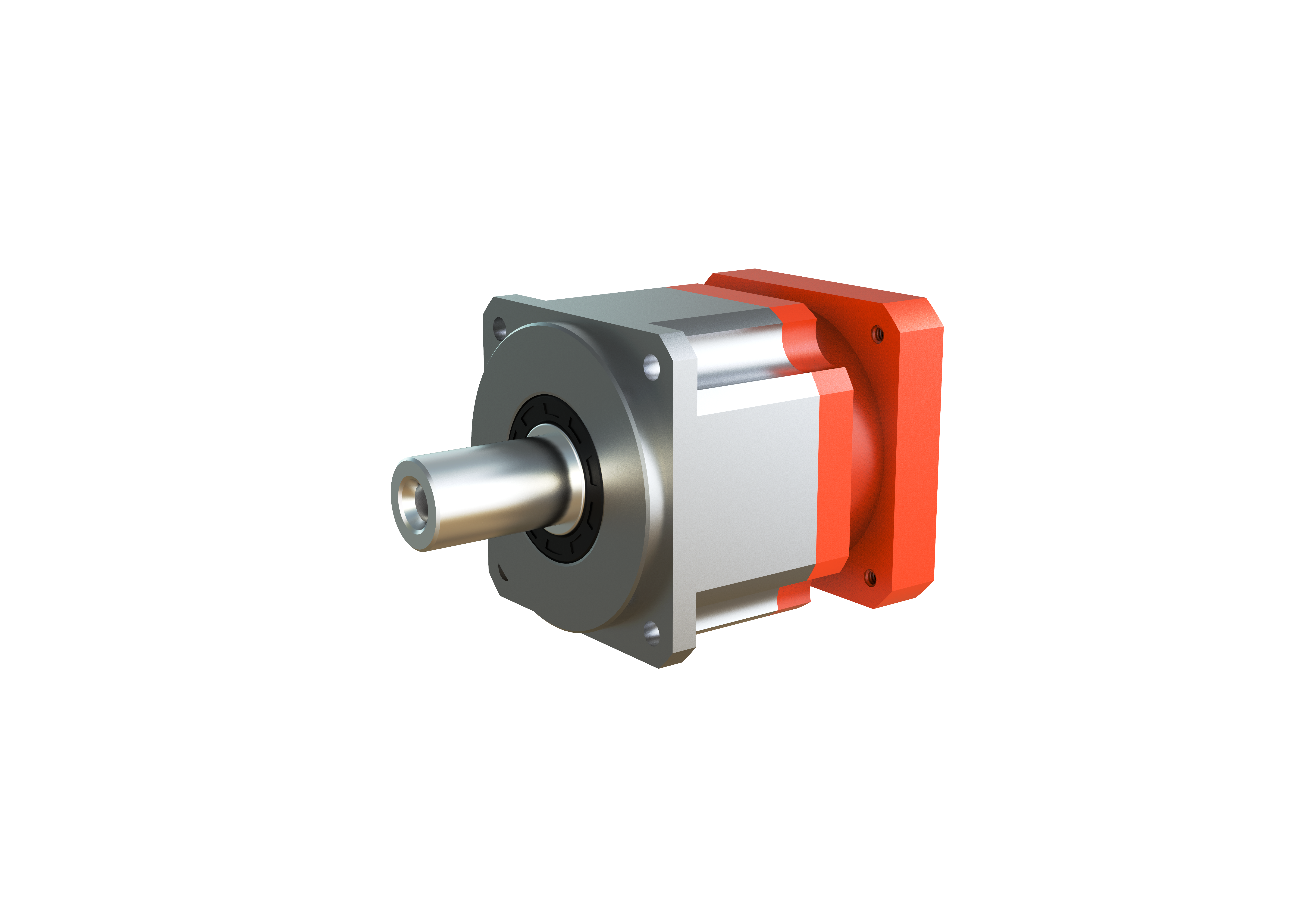

Planetary gearbox boast advantages such as compact structure, low backlash, high rigidity, high precision, high output torque, and low operating noise, achieving a transmission efficiency of over 95%. Due to their high precision characteristics, gear manufacturing is complex, requiring advanced precision machining techniques. High-quality planetary gear reducers not only possess the aforementioned superior performance but also feature lifetime oil-free and maintenance-free operation, reducing future maintenance costs. Planetary gear reducers are mostly installed on servo motors and stepper motors to meet dynamic control needs such as increased output torque and precise positioning.

Industries where reducers are used

Reducers are mechanical transmission devices used in many sectors of the national economy. The industry encompasses various types of reducers, planetary gearbox, and worm reducers, as well as various specialized transmission devices such as speed increasers, speed regulating devices, and various composite transmission devices, including flexible transmission devices. Product and service areas include metallurgy, non-ferrous metals, coal, building materials, shipbuilding, water conservancy, power, construction machinery, and petrochemical industries.

my country's speed reducer industry has a history of nearly 40 years, and speed reducers are widely used in various sectors of the national economy and defense industry. Industries such as food processing, light industry, power machinery, construction machinery, metallurgical machinery, cement machinery, environmental protection machinery, electronics, road construction machinery, water conservancy machinery, chemical machinery, mining machinery, conveying machinery, building materials machinery, rubber machinery, and petroleum machinery all have a strong demand for reducers.

Recommended Gearbox Manufacturer - Zhejiang Wuma Drive Co., Ltd.

Founded in 1995, Zhejiang Wuma Drive Co., Ltd. is located in the coastal economic zone. Inheriting nearly 30 years of manufacturing experience in the transmission field , the company specializes in producing over 10 series of products, including RV series worm reducers, R, K, F, and S series hardened helical gearbox, and hypoid reducers. The company boasts a high-caliber talent pool, including experienced full-time PhDs, postgraduates, senior engineers , and recipients of the Wenzhou High-Level Special Support Program . It has participated in the formulation of 12 industry and group standards , holds 35 patents , and has received numerous research awards, including the Zhejiang Industrial Science and Technology Award , Wenzhou Major Science and Technology Innovation Project, and the Lishui Green Valley Elite Innovation Leading Program

. The company has passed ISO9001:2000 quality management system certification, ATEX EU explosion-proof system certification, CE certification, etc., and has successively won various honors such as national high-tech enterprise, national torch program enterprise, and national specialized and innovative "little giant" enterprise.

It has now formed a "Wu Ma" brand , two major manufacturing bases for speed reducers and mixers , and a highly efficient and collaborative transmission ecosystem.

Hot News

Hot News2026-02-24

2026-02-22

2026-02-20

2026-02-18

2026-02-16

2026-02-14