-

Hypoid Gear Reducer: A "Power-Saving Marvel" for Green Manufacturing, Making Production Lines Fast and "Green"!

Hello everyone, It's Bella again~ , ZHEJIANG WUMA DRIVE CO.,LTD.'s 30th Anniversary Tweets! Are manufacturing business owners always struggling with the dilemma of meeting orders, saving on electricity bills, and dealing with environmental inspection...

Feb. 03. 2026 -

The effect of temperature on the normal operation of the speed reducer Key words: gearboxes, gearbox,reducer,speed reducers,reducers,speed reducer

Temperature is one of the most important factors affecting the performance and efficiency of a speed reducer. The following is a detailed analysis of how temperature affects speed reducers: Aging of Insulation Materials: The lifespan of the insulatio...

Feb. 02. 2026 -

Hidden Dismantling Technician vs. The Perfect Anti-Loosening Partner: The Philosophy of Details on RV Gearbox Screws

Have you ever noticed that the screws on the input flange of an WMRV reducer gearbox always come with a flat washer and a spring washer? This seemingly simple combination is a key line of defense against the equipment's "invisible killer"—vibra...

Jan. 31. 2026 -

Gearboxes and Servo Motors in Use

In industrial automation, the perfect combination of servo motors and gearboxes is key to achieving high-precision motion control. However, in actual selection and integration, engineers often face a thorny problem: servo motors come in many brands w...

Jan. 30. 2026 -

What is the pressure angle of gears?

An appropriate gear pressure angle helps the reducer achieve the best efficiency. If the pressure angle is too large or too small, it will cause wear, noise and even premature loss of function.In this article, we will tell you how to select the type ...

Jan. 29. 2026 -

The impact of oil viscosity index on the stable operation of the gear reducer.

The lubricating oil directly affects the equipment's operating efficiency and service life. Among the many parameters of oil, viscosity is the most crucial physical indicators. Viscosity grade and viscosity index is two key parameters of viscosity wh...

Jan. 28. 2026 -

New Reducer, Why Does the Keyway Fail First?

So you just installed a new reducer, but the keyway wore out or got damaged way too fast. Super annoying, right? Usually, it comes down to a few common issues. 1.The key size is off. Maybe the key itself is too narrow, too thin, or just the wrong hei...

Jan. 27. 2026 -

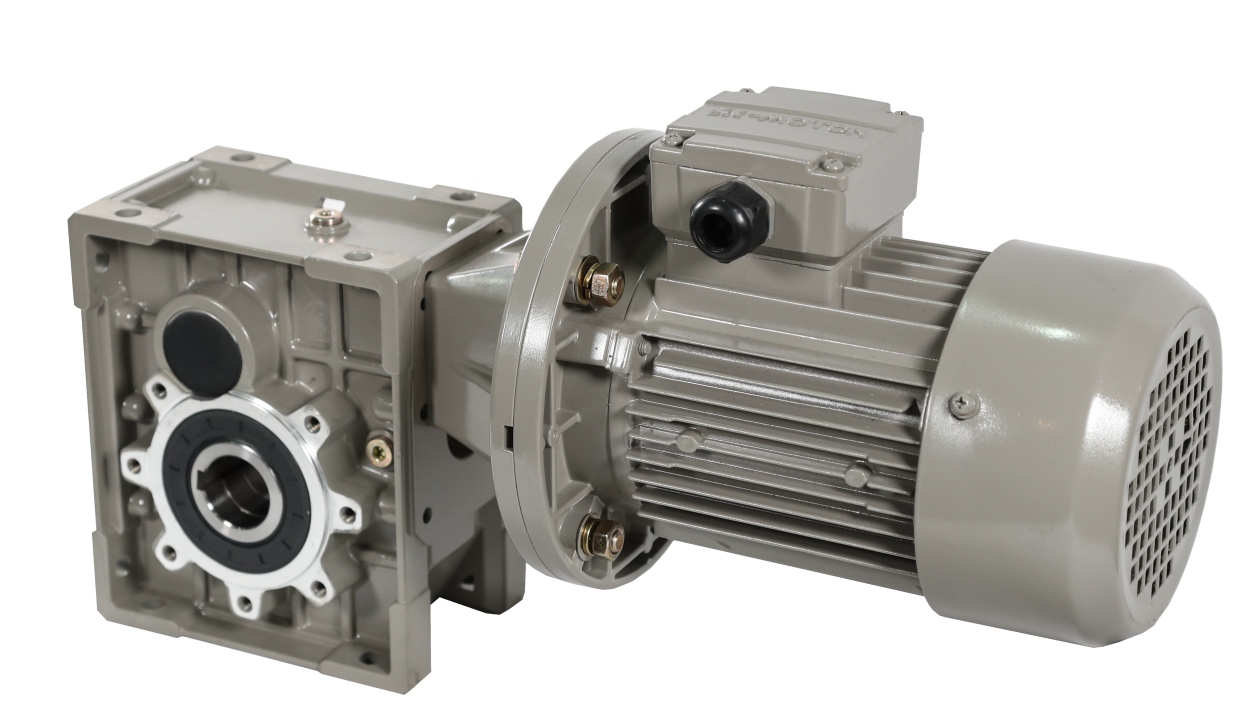

Golden Partner——Reducer and Motor

Stepping into a factory workshop, you'll notice an interesting phenomenon: almost every motor is accompanied by a component called a “reducer”. Unlike a motor that roars and generates power, it quietly becomes the “core regulat...

Jan. 26. 2026 -

Our C1-C5 full-level anti-corrosion coating line provides precise matching for your equipment.

In complex and ever-changing industrial environments, corrosion protection for gearboxes is never a one-size-fits-all solution. Over-protection leads to wasted costs, while insufficient protection results in a shortened equipment lifespan. We underst...

Jan. 25. 2026 -

Key factors for reducer operating coefficient and efficiency Key words: gearbox,speed reducer,service factor

Introduction to Operating Factors The operating factor of a gearbox, which is the ratio of input power to the gearbox's rated power, reflects the gearbox's operational stability. A higher operating factor indicates more stable operation. Generally, a...

Jan. 24. 2026 -

What effects does gear backlash have on gears

Gear backlash refers to the gap produced after gears mesh, which has a significant impact on gear performance. A certain gear backlash is beneficial for gear lubrication, but excessive gear backlash will accelerate gear wear, reduce gear efficiency a...

Jan. 23. 2026 -

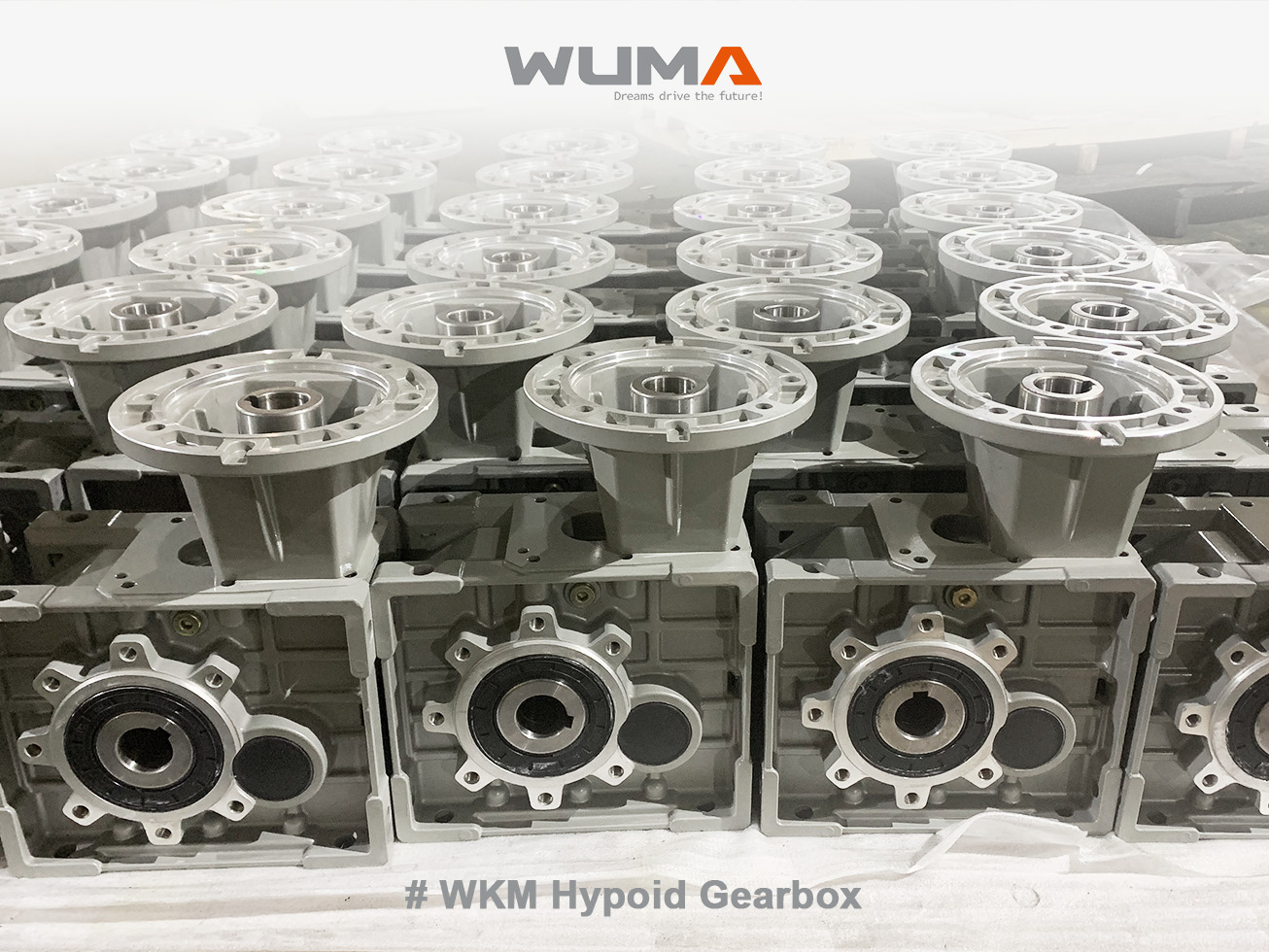

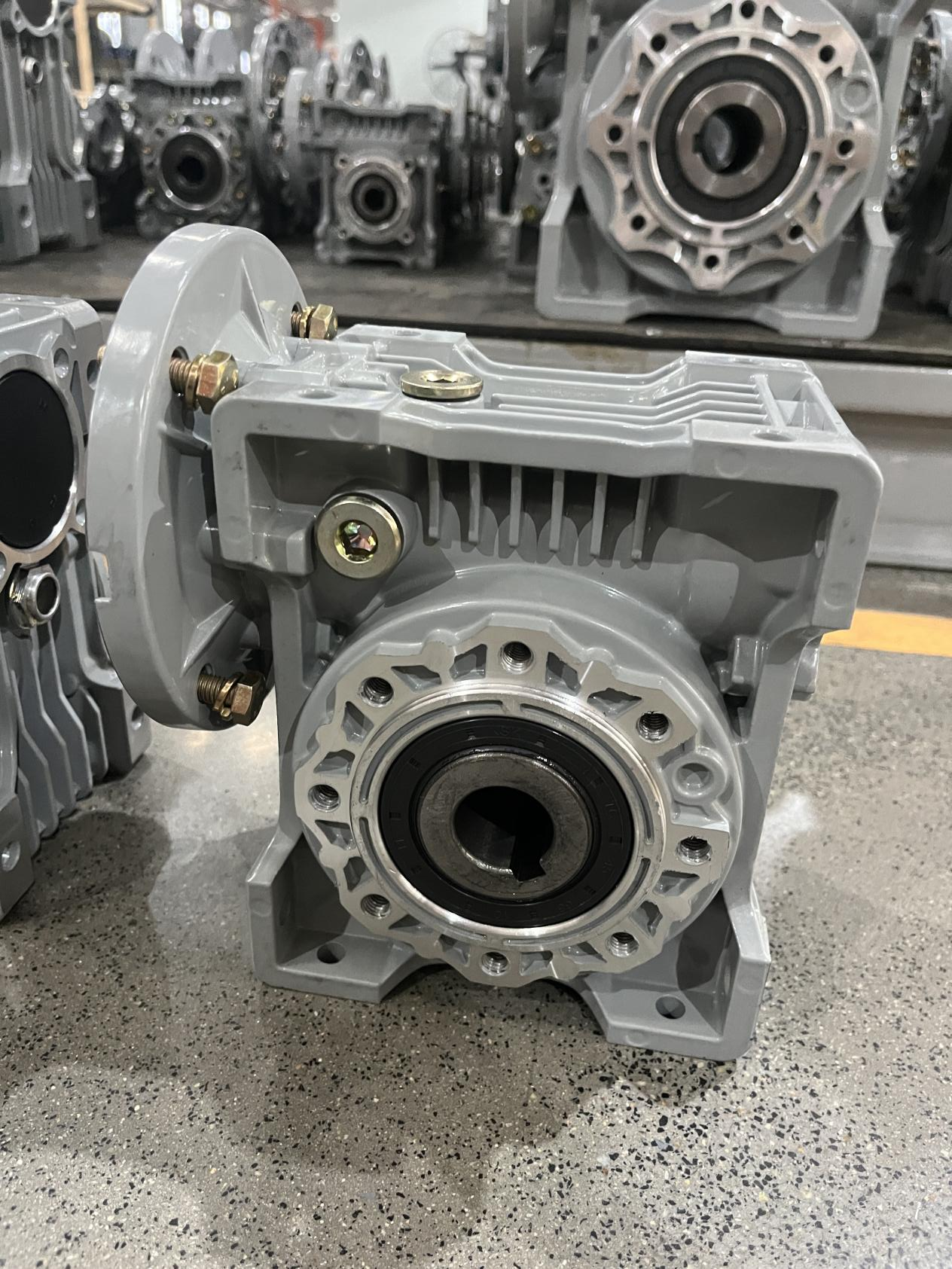

Worm Gear vs. Hypoid gearbox: The Ultimate Showdown of Efficiency and Cost

Faced with the demands of compact spaces and right-angle transmissions, we have traditionally opted for classic worm gear reducers (represented by the WMRV/WDVF/WMVF series). However, a formidable challenger has emerged – the Hypoid reducer (WK...

Jan. 23. 2026