An industrial gearbox is a power transmission device that uses a gear or worm and gear speed converter to reduce the higher speed of an motor to the required speed while achieving greater torque.

The right industrial gearbox can help our equipment achieve higher efficiency, reliability and longer lifespan. It ensures effective power transmission, speed and torque regulation, direction changes, and matching of motor output with load requirements.

There are many types of industrial gearboxes, the most common and core types being: worm gear reducers, gear reducers, planetary gearboxes and cycloidal gearboxes. According to different inside gear type and assemble method, different reducer will show their distinct characteristics in different aspects.

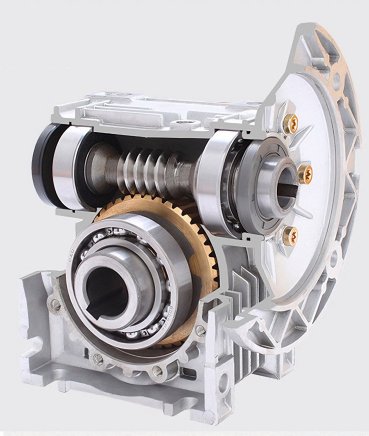

1.Worm Gear Reducers

Worm gear reducers perform outstanding advantages in handling heavy loads functions. It has compact construction inside and has a high load capacity while also being the smoothest and quietest gear system available. Worm gear reducers have a large diameter screw, and this screw aligns the teeth on the machine’s periphery.

Worm gear reducers have the following advantages:

2.Gear Reducers

2.Gear Reducers

Power is vital for running industrial machines. To move energy from one part to another effectively, different types of transmission devices are used together to fit various needs. Thanks to their efficiency and reliability, these devices are essential in keeping equipment running smoothly.

Gear drives are used to send power over short distances at a set speed. They take up less space and are simpler to set up than many other transmission options. In most cases, gear drives also lose less energy than belt or chain drives.

Common types of gear reducers include:

2.1.Helical Gear Reducer

Helical gear reducers deliver maximum grinding force when gears rotate in the same direction. The angled teeth design allows smoother power transmission between gears. This also increases the contact area between teeth, reducing stress and wear.

The helical shape helps spread load evenly across the gear surface, improving durability and service life. These reducers can transmit power through either coaxial shafts (as in WUMA’s WR Series) or parallel shafts (as in WUMA’s WF Series). WUMA’s helical gearbox features a unique housing design with mounting dimensions that match SEW models.

Compared to other industrial gearboxes, helical gear reducers are more compact, consume less power, and are widely used in high-power, high-load applications—such as in rubber and cement production. They are also suitable for lower-power uses like grinders, coolers, and conveyors.

Key benefits of helical gear reducers include:

2.2.Bevel-Helical Gear Reducer

The bevel-helical gear reducer features a 90° angle between input and output shafts, making efficient use of housing space. Its compact design reduces speed and increases torque for non‑parallel shafts—ideal for tight installation spaces. When you need both powerful drive performance and a space‑saving layout, our helical‑bevel gear reducers (WUMA WK series) provide the solution, with torque ranging from 80 to 50,000 Nm.

Bevel gear reducers are commonly used to change shaft direction, delivering high output torque, strong load capacity, and long service life. They handle motion transmission between non‑parallel shafts and are widely applied in industries such as aerospace, pharmaceuticals, mining, and textiles.

Key advantages of bevel gear reducers include:

2.3Helical-Worm Gear Reducer

Its simple design offers a cost-effective solution. This reducer fits well in tight spaces. Use the S-series gearboxes (such as WUMA WS Series) to handle basic tasks in machinery or factory applications.

The combination of worm gears and helical gears works more efficiently than a standard worm gear reducer. Sliding friction keeps operation smooth and quiet.

3.Planetary Gearbox

Planetary gearboxes are commonly used in industries that require high precision, such as aerospace, robotics, and machine tools.

The name "planetary gearbox" reflects its internal layout: planetary gears rotate around a central sun gear, much like planets orbit the sun.

In operation, the planetary gears mesh with both the sun gear and the ring gear to achieve a high reduction ratio. Their compact design supports efficient power transfer and high torque output in confined spaces.

Key advantages of planetary gearboxes include:

4.Cycloidal Gearbox

A cycloidal gearbox, also known as a cycloidal pinwheel reducer, is based on planetary transmission principles and cycloidal-pin gear meshing. Its double eccentric sleeve drives a cycloidal wheel in combined orbiting and rotating motion, using the pin gear and cycloidal wheel to deliver efficient, high-torque performance.

The unique internal structure ensures high precision and smooth motion. These gearboxes offer high reduction ratios and strong torque with very little gear play. They are commonly used in metallurgy, chemical processing, lifting, and textile industries.

The speed reducers mentioned above are all products mainly manufactured by Wuma and are widely praised in many countries and industries.

If you require a speed reducer, please contact us for a customized transmission solution.

Your operating conditions are unique. Submit your technical parameters (such as power, speed, torque, speed ratio, etc.), and our sales representatives will provide you with professional selection advice and a quotation.

Hot News

Hot News2026-02-24

2026-02-22

2026-02-20

2026-02-18

2026-02-16

2026-02-14