The Importance of Self-Locking Function in Industrial Transmission

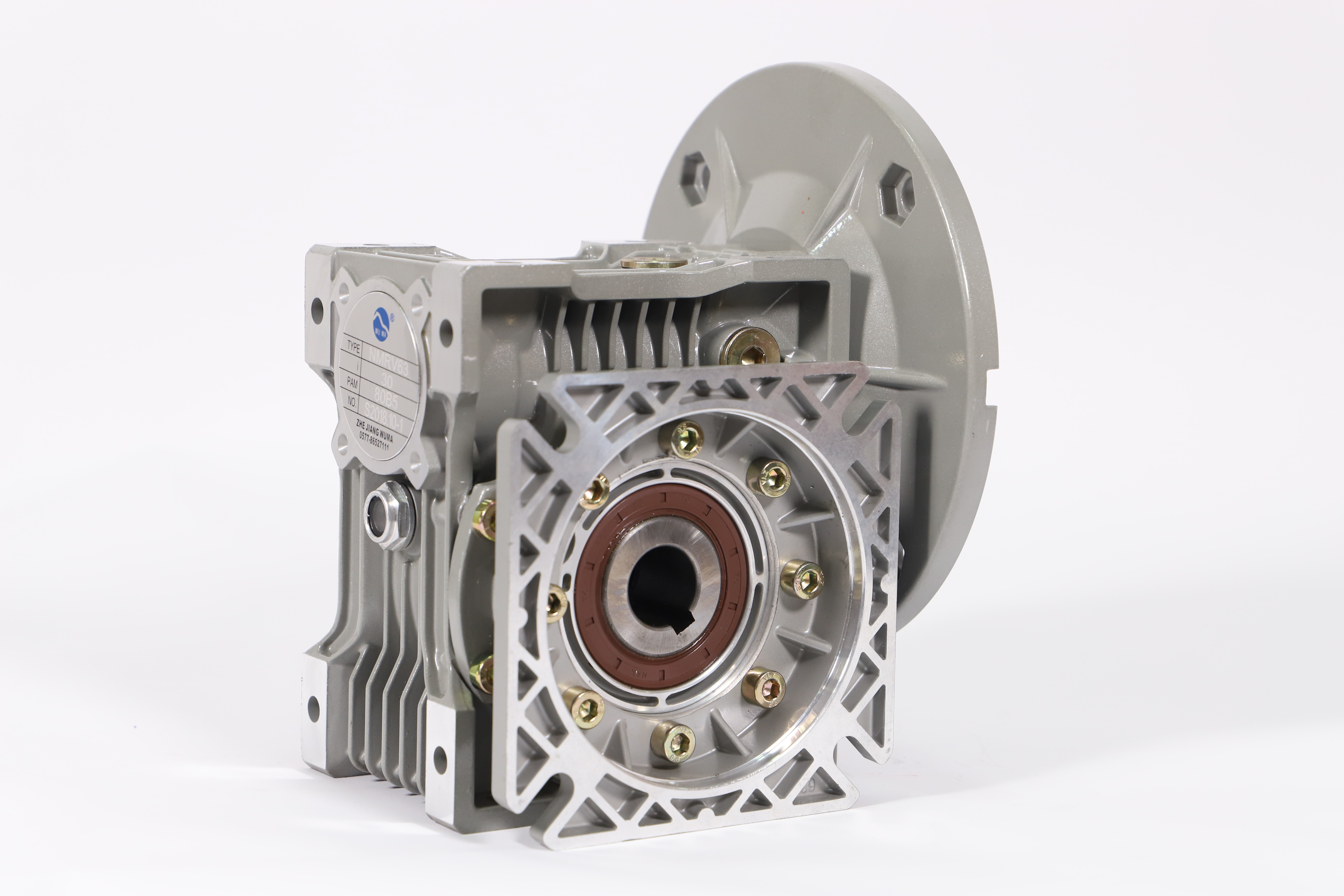

In the fields of industrial automation and mechanical transmission, worm gear reducers have become the preferred choice for many precision applications due to their unique transmission characteristics and reliable performance. Particularly noteworthy is their built-in self-locking function, which provides an irreplaceable guarantee for the safety and operational stability of the equipment.

The mechanical principle of worm gear self-locking

Mechanical relationship between lead angle (λ) and equivalent friction angle (ρ)

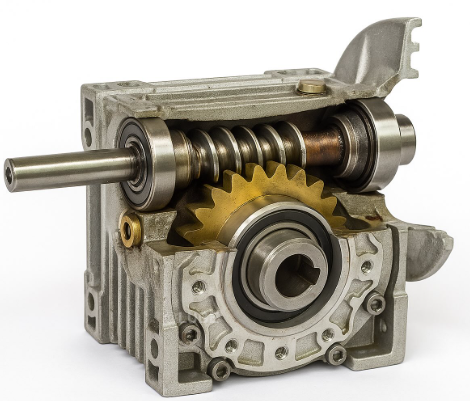

When the worm is the driving component, the meshing of its helical surface with the worm wheel teeth can be equivalent to an inclined plane transmission model. If the lead angle is less than the equivalent friction angle converted from the material friction coefficient (i.e., λ < ρ), the axial force component required for the worm wheel to reverse drive will be unable to overcome the static friction resistance, thus forming a mechanical self-locking mechanism. This is the fundamental condition for achieving reliable reverse stopping.

Analysis of conditions for self-locking failure

When the lead angle (λ) of the worm exceeds the equivalent friction angle (ρ) of the material, the system will lose its self-locking capability. For example, multi-start worms, due to their large lead angle, may have insufficient frictional resistance to counteract the reverse driving force, thus failing to achieve self-locking.

Secondly, using materials with low friction coefficients, or excessive lubrication during assembly or maintenance leading to a significant reduction in the actual friction coefficient, can also compromise the critical conditions for self-locking.

Operating conditions directly impact self-locking reliability. High temperatures can cause a decrease in lubricant viscosity, weakening the oil film strength and altering the boundary lubrication state of the friction pair. Simultaneously, thermal expansion of components can change the meshing clearance, affecting the pressure distribution and friction balance on the contact surfaces. Continuous external vibrations or impact loads can also disrupt the stable engagement of the friction pair, inducing momentary reverse sliding under dynamic conditions.

How to ensure the reliable self-locking of a worm gear reducer?

Dynamic operating condition simulation: Considering the potential impact of start/stop inertia, external vibration and thermal effects on friction conditions.

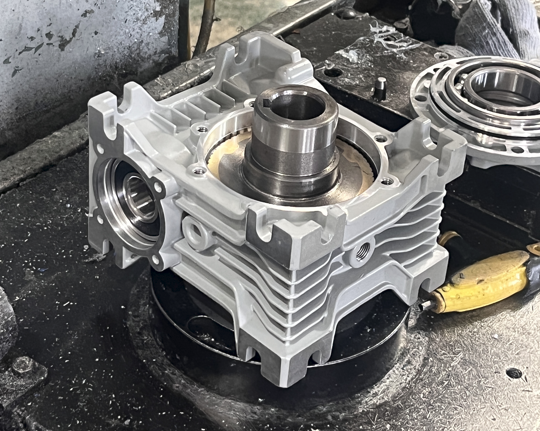

Materials and process certification: Ensure the thermal stability, wear resistance and consistent friction characteristics of the friction pair materials.

Mastering self-locking reliability through scientific understanding and precision engineering

The self-locking function of worm gear reducers is a valuable inherent characteristic, but it is by no means an unconditional and absolute attribute. It is the result of the combined efforts of materials science, tribology, precision manufacturing, and operational condition management. Wuma Transmission adheres to a scientific understanding as its foundation, transforming the potential self-locking capability of worm gears into definite safety and reliability in customer equipment through precise engineering design and rigorous process control. Choosing Wuma Transmission means choosing a partner who respects transmission safety and relentlessly pursues technical details, jointly driving a safer and more robust industrial future.

Hot News

Hot News2026-02-24

2026-02-22

2026-02-20

2026-02-18

2026-02-16

2026-02-14