The meshing gap (i.e., tooth side clearance) of the worm gear is a key parameter to ensure the stability of transmission and reduce shock and noise. If it is too small, it will aggravate wear, heat and even jamming. The adjustment method needs to be determined according to the structural type of the reducer (split box, integral box, etc.), and the core is to adjust the meshing gap by changing the relative position of the worm gear and the worm.

The effect of excessive worm clearance of the worm gear:

1.Reduced transmission accuracy: Excessive mating clearance of the worm gear will lead to a decrease in the accuracy of the transmission, thereby affecting the overall performance of the machine.

2.Louder noise: Excessive clearance will significantly increase the impact sound of worm gears and worms, which will pollute the environment around the machine and is not conducive to environmental management at the production site.

3.Decreased transmission efficiency: Excessive mating clearance will lead to increased friction losses, resulting in a decrease in transmission efficiency.

There are several main methods for adjusting worm gear clearance:

1.Double Lead Worm Method:

Introduction: The lead on both sides of the worm is different. The meshing clearance is adjusted by axially moving the worm.

Advantages: This is a standard and widely used method for eliminating clearance, with high reliability and stability.

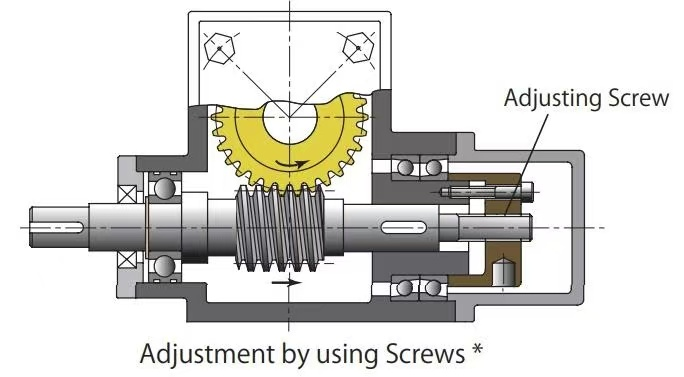

2.Changing the Radial Distance of the Worm Gear:

Introduction: The center distance is changed by adjusting the installation position of the worm gear or worm (e.g., using an eccentric sleeve), thereby reducing the clearance.

Advantages: This method is effective in practice, is a common adjustment method, and is relatively simple to operate.

3. Adjusting the Worm Front clearance:

Introduction: The clearance at the worm front end has a significant impact on the reverse clearance of the worm gear. Adjusting this clearance can reduce the reverse clearance.

Precautions: When adjusting, ensure the worm front end is fixed and stable.

4. Adding Spring Washers:

Introduction: Adding spring washers to the worm gear can fill the reverse clearance and reduce its size.

Advantages: Spring washers have a certain degree of elasticity and compensation ability, and can adapt to certain clearance changes.

5. Using Preload Nuts:

Introduction: Preload nuts apply torque to cause the nut itself to undergo elastic deformation, thereby filling the reverse clearance.

Precautions: The torque must be controlled during preload to avoid over-preload and damage.

6. Axial Preload:

Introduction: By adding bushings to the worm gear shaft, increasing the pressure angle, or using fastening devices, axial preload is generated between the worm gear and the worm, thereby reducing the axial clearance.

Advantages: Effectively reduces axial clearance and improves transmission accuracy.

7. Using clearance - Free Materials:

Introduction: To reduce axial clearance, clearance - free materials can be selected for processing and manufacturing, such as ceramics and graphite. Advantages: clearance-free materials have high hardness and wear resistance, and can maintain a small clearance for a long time.

Besides, during the operation of worm gears, the quality of lubricating oil directly affects the wear resistance and transmission efficiency of worm gears. Therefore, if the lubricating oil is contaminated with impurities or stored for too long, it will affect the size of the mating gap. In this case, a qualified lubricant will need to be replaced.

In addition, the following should be noted during the elimination of clearance:

Adjust the immersion depth of the worm gear to avoid improper immersion depth leading to increased clearance.

Ensure the surface finish and precision of the worm gear and worm to reduce clearance.

Regularly check the wear condition of the worm gear and worm, and replace severely worn parts in a timely manner.

In short, the large mating clearance of the worm gear will affect the transmission accuracy, noise and transmission efficiency of the machine. Therefore, during the operation of the machine, effective solutions should be taken in time to achieve the purpose of ensuring the normal operation of the machine.

Hot News

Hot News2026-02-24

2026-02-22

2026-02-20

2026-02-18

2026-02-16

2026-02-14