Hello everyone, this is Bella from ZHEJIANG WUMA DRIVE CO.,LTD. We have more than 30 years of experience in production gearboxes and 25 years of export experience in the gearbox.

Last week, I introduced how to change the lubricating oil in a WMRV worm gearbox. Today, let me introduce what kind of lubricating oil should be selected for different gearboxes.

With the continuous development of industry, the role of speed reducers in the transmission field has become increasingly prominent. However, this has also brought us many problems, such as the lubrication of speed reducers.

During the operation of speed reducers, the quality of lubrication of rotating parts directly affects the service life of the speed reducer. The brand, viscosity grade, and amount of oil used in the speed reducer are very important issues, and we should pay sufficient attention to and understand them.

Three minor questions:

First, this gearbox has been using this brand of lubricant, too expensive. Can I change to a cheaper one?

Second, I feel the lubricant oil isn't very good. Can I upgrade to a higher-performance lubricant oil that better suits my current operating conditions?

Third, most gearboxes use imported brand lubricants. Can I directly replace it with a Chinese brand of lubricant oil?

——————————————————————————————————————————————————————————————————————————

Brief introduction:

Lubricating oils are generally has two types: ① Vehicle gear oils (we won't discuss these here). ② Industrial gear oils.

Industrial gear oils are further divided into three categories: ① Enclosed gear oils. ② Open gear oils. ③ Worm gear oils.

The standard in China is GB5903-95.

For example, industrial enclosed gear oils can be divided into three types:

① L-CKB anti-rust and anti-oxidation type, also known as ordinary industrial gear oil. This lubricant is equivalent to AGMA 250.04 R&O.

② L-CKC medium-load gear oil. This lubricant is equivalent to AGMA 250.03 EP.

③ L-CKD heavy-duty gear oil (mostly used in large gearboxes). This lubricant's standard is AGMA 250.04 EP (American Gear Manufacturers Association standard).

(Also L-CKE,L-CKT,L-CKS,L-CKH,L-CKJ)

For gearbox lubricants, especially for large, low-speed, heavy-duty gearboxes, high-viscosity extreme-pressure heavy-duty gear oils should be selected whenever possible. Special operating conditions also require consideration of specific requirements such as rust prevention, corrosion prevention, high-temperature resistance, anti-foaming, anti-emulsification, oxidation resistance, and extreme pressure. Heavy-duty gearboxes typically use VG220/VG320 viscosity oils. The viscosity of the gearbox oil must be appropriate (according to the gearbox design requirements); it cannot be too high or too low. Higher viscosity provides better protection against various types of damage to the gear teeth and reduces gear wear. However, excessively high viscosity makes it difficult for mechanical impurities to settle, reducing the lubricant's flushing effect and heat absorption/cooling effect on the gear teeth, leading to high temperatures and poor lubrication in the meshing area. Simultaneously, impurities suspended in the oil entering the meshing area can easily cause scuffing and wear. Furthermore, excessive viscosity increases transmission resistance, overall machine temperature, and power consumption, while also reducing the oil's stability and anti-emulsification properties. However, high viscosity has obvious benefits in reducing noise and preventing leakage. For gearboxes that are frequently overloaded, high viscosity can also play a certain role in protecting the gear surface. The correct approach is to choose the appropriate viscosity, high-quality base oil additives, and especially extreme pressure properties are very important.

Below are some recommended imported lubricating oils for your reference.

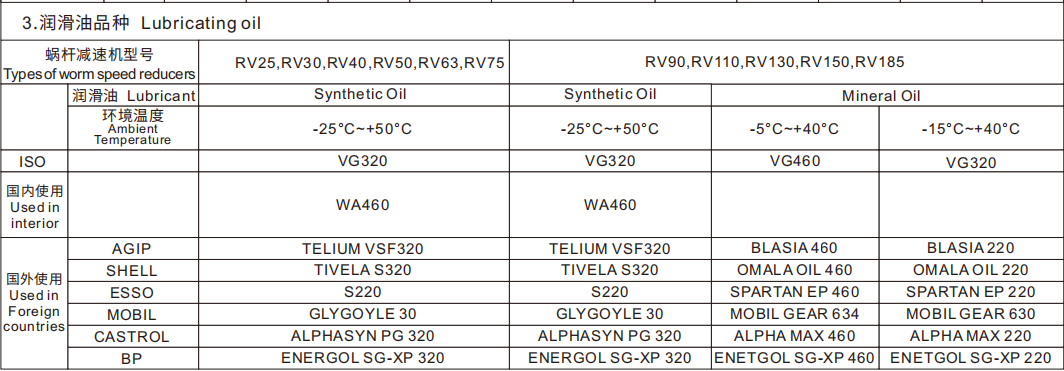

First, let's look at recommended worm gear oil brands:

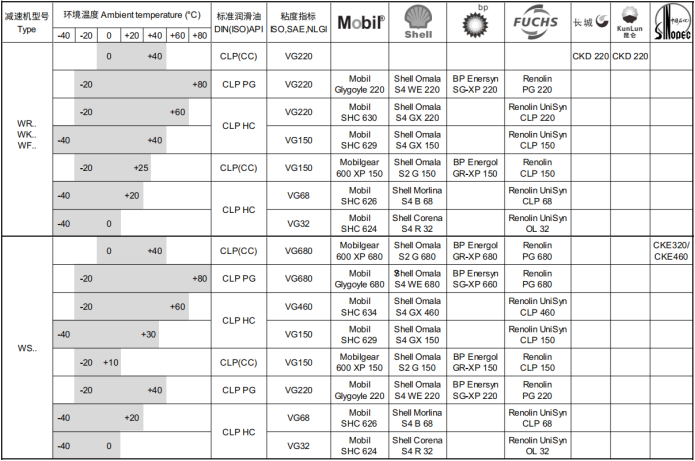

Secondly, recommendations for gear oil brands:

In a words, lubrication plays a crucial role in the lifespan of a gearbox, from installation to disposal. Improper oil selection or poor lubrication can damage gears, shorten the equipment's lifespan, and increase operating costs. Excluding other factors, proper and reasonable lubrication can extend the equipment's lifespan by 1 to 5 times. Therefore, we must carefully consider oil selection and usage to ensure the equipment operates economically, efficiently, and environmentally friendly.

Hot News

Hot News2026-02-24

2026-02-22

2026-02-20

2026-02-18

2026-02-16

2026-02-14