Gear Types and Materials

1. Gear types

From the perspective of smooth transmission and low noise, helical cylindrical gears have more teeth in contact simultaneously, resulting in a more stable change in overall meshing stiffness. Therefore, vibration and noise may be lower than those of spur cylindrical gears, sometimes as low as approximately 12 dB. For herringbone gears, due to the requirement for strict alignment, even small errors or uneven wear can affect the load distribution and transmission smoothness. Therefore, among cylindrical gears, helical cylindrical gears are the best type for reducing noise. From 1969 to 1987, Professor A. Atfia of Ain-Shams University in Cairo, Egypt, conducted experimental research on involute helical gears, single-circular-arc gears, and double-circular-arc gears. He compared the noise of these three tooth profiles under different loads and speeds. The study showed that among these three tooth profiles, involute helical gears had the lowest noise and were least affected by the transmitted load and operating speed, followed by single-circular-arc gears, with double-circular-arc gears being the worst.

2. Gear materials

Heat Treatment, and Lubrication Methods: These factors all affect system noise. Generally speaking, using materials with good damping properties to manufacture gears can reduce noise. However, materials with good damping properties generally have low strength and cannot be used in all situations. For example, phenolic resin and nylon are often only used to manufacture light-load gears for light industrial machinery such as sewing machines. To reduce noise, sulfurizing or copper plating can be applied to the tooth surfaces of load-bearing steel gears. The purpose of sulfurizing the tooth surfaces is to reduce the coefficient of friction. Copper plating has been used on turbine gears to improve the contact accuracy of the gears. Gear heat treatment also affects noise. For example, after quenching, the damping properties of gears deteriorate, and the noise increases by 3-4 dB. Therefore, gears with low strength and wear resistance requirements do not need to be quenched. As for the influence of lubricating oil and the method of filling, it is generally believed that noise decreases as the oil volume and viscosity increase. This is because lubricating oil has a damping effect, which can prevent direct contact between meshing tooth surfaces. When using oil bath lubrication, the gear noise varies depending on the oil level; that is, different gearboxes have different optimal oil levels.

Gear geometric parameters

1. Module

1. Module

When transmitting a large load, the dynamic excitation of gear meshing is mainly caused by the bending deformation of the gear teeth, and the bending stiffness of the gear teeth is proportional to the module. Therefore, increasing the module can reduce the dynamic excitation of the gear teeth, thereby reducing noise. However, when transmitting a small load or no load, the situation is different. At this time, the influence of gear tooth error will be much greater than that of gear tooth deformation. We should consider the influence of the module size on noise from the perspective of gear machining error. For example, the pitch error ΔP can be obtained by the following formula:

ΔP=C1 +C2M+C3 (1)

where

do——gear pitch circle diameter

M——module

C1, C2, C3——related constants

And the tooth profile error Δf can be calculated by the following formula:

Δf=C4M+C5 (2)

where C4 and C5 are related constants.

It can be seen from formulas (1) and (2) that the above two errors are directly related to the module, and the larger the module, the larger the tooth profile error and the greater the noise. Therefore, when transmitting small loads or no loads, the module should be as small as possible, provided that the gear strength allows.

2. Number of gear teeth

If the module remains unchanged, changing the number of teeth will change the gear diameter and gear surface area. Thus, the change in the noise radiation area of the gear will cause a change in noise. Generally speaking, the magnitude of noise is mainly determined by the radiation area of the noise rather than the energy of the vibration source. According to the acoustic principle, if the gear is regarded as a circular plate, the sound power WR radiated into the air can be calculated by

the following formula :

(3) Where: F——effective value of the excitation force that varies according to a sine law

R——circular plate diameter

o——surface density

p——air density

ω——angular frequency

C——constant

From formula (3), it can be seen that as the diameter of the circular plate increases, the noise will increase sharply. Therefore, when designing gears, the gear diameter should be reduced as much as possible. In addition, it can be seen from formulas (1) and (2) that the tooth pitch error is related to the gear diameter, while the tooth profile error is not related to the diameter. Therefore, reducing the diameter will not increase the difficulty of achieving the gear machining accuracy.

3. Tooth width

The reason why changes in tooth width cause changes in noise lies in the different energy attenuation. Therefore, gears with larger tooth widths have better attenuation performance, resulting in lower noise.

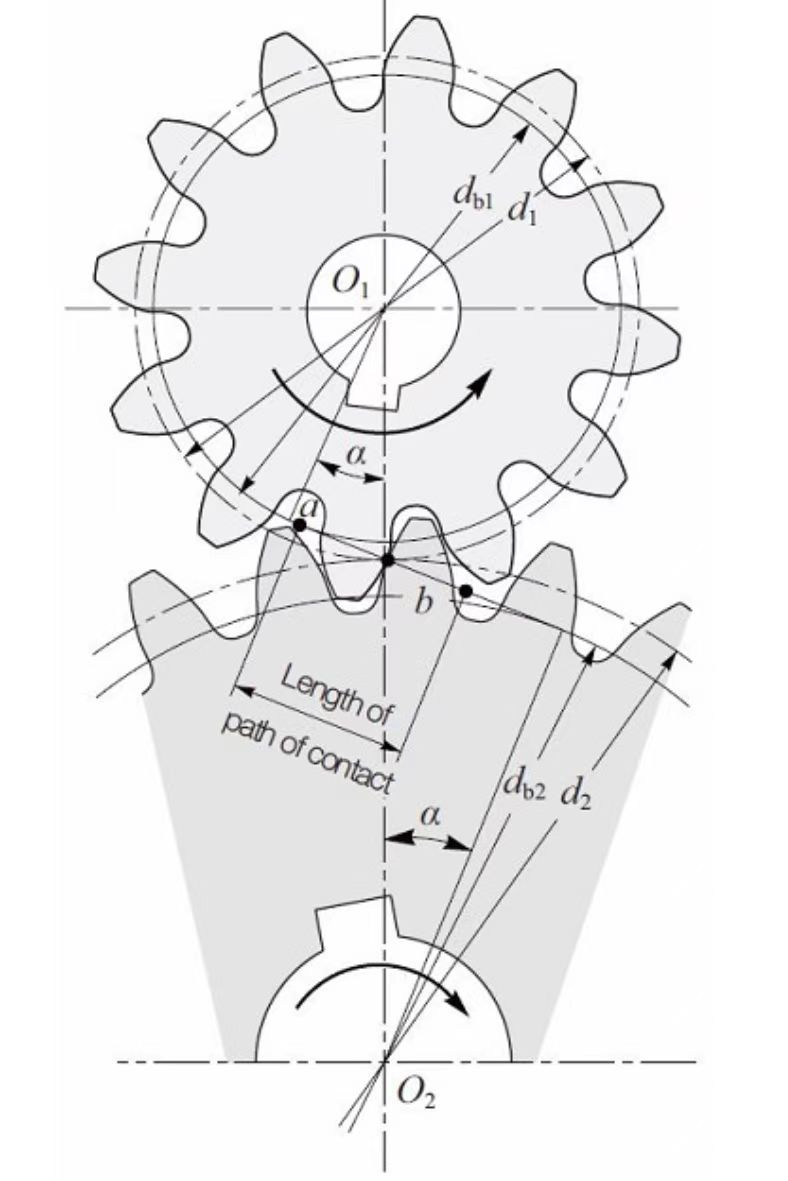

4. Contact ratio

Increasing the contact ratio: The contact ratio can reduce the noise of gear transmission. First, increasing the contact ratio reduces the load on a single pair of teeth. This reduces the load impact during meshing and disengagement, thus lowering gear noise. Second, as the number of contact teeth increases, the transmission error of a single pair of teeth is averaged, thereby reducing the dynamic excitation of the teeth. In addition, almost all gear parameters that affect gear noise are actually due to their influence on the contact ratio. For example, for cylindrical gears with a contact ratio of 1-3, reducing the pressure angle, reducing the module, and slightly increasing the addendum all reduce gear noise due to the increased contact ratio. Of course, reducing the pressure angle increases the flexibility of the teeth and also reduces dynamic excitation, which is beneficial to noise reduction.

5. Helix angle

Since helical gears gradually enter mesh from one end of the tooth, the meshing impact is small and the noise is low. Generally speaking, as the helix angle increases, the contact ratio increases and the noise decreases. However, the noise reduction effect is worse when the helix angle is larger than when the helix angle is smaller. This is because a larger helix angle makes machining and installation more difficult, affecting the actual overlap.

6. Tooth modification, shaping, and displacement

In the actual working state of gears, the deformation of the teeth, drive shaft, and gearbox will cause interference and impact during meshing, resulting in strong vibration and noise. Therefore, modification, shaping, and displacement can be used to compensate for meshing deformation to reduce vibration and noise.

Hot News

Hot News2026-02-24

2026-02-22

2026-02-20

2026-02-18

2026-02-16

2026-02-14