1.The composition and operating principle of worm gear reducer

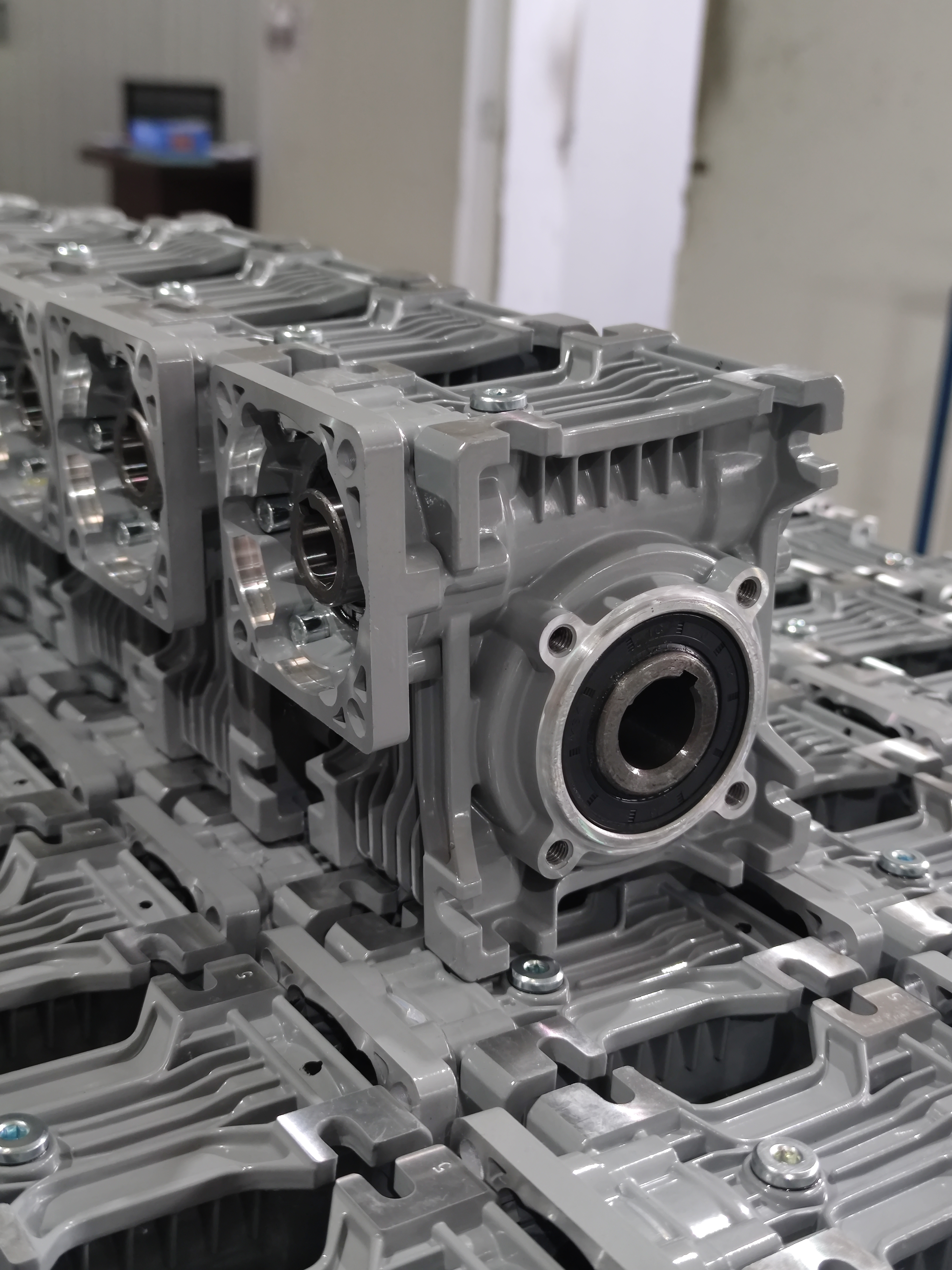

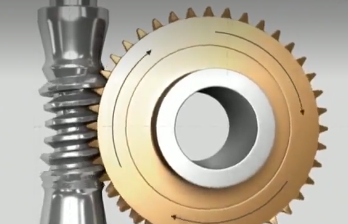

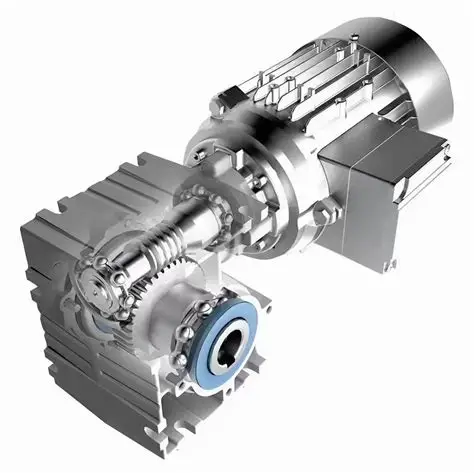

The worm gear reducer is an industrial device that uses gears to reduce the speed of a motor to a required speed while providing a relatively large torque. RV series worm gear reducer includes worm gear, shaft, bearings, housing, and other accessories. The housing, the worm gear, and the bearing and shaft assembly are main parts in worm gear reducer. The housing is the foundation for all other components in the worm gear reducer; it is a crucial component that can support and fix the shaft components, and ensures the correct position of all components. Worm gear is a crucial spare part of worm gear reducer to transmit motion between two shafts, while the bearings and shaft primarily transmit power and improve efficiency.

Its function is to reduce the speed of a high-speed rotating power source and transmit the power to the output shaft, while reducing the output shaft speed and increasing its output torque, providing suitable speed for the aimed equipment. It belongs to the mechanical equipment. Worm gear reducers have some advantages than other reducer types, such as small size, simple structure, strong load-bearing capacity, as well as high transmission efficiency and precision. They are widely used in engineering machinery of many industries, such as chemical, food, pharmaceutical, power, textile, printing, and agricultural machinery. This is a great choice for modern industrial equipment to achieve high torque, high speed ratio, low noise, and high stability.

2.Common faults and solutions of worm gear reducers

2.1Gearbox Overheating

To improve efficiency, worm gearreducersgenerally use non-ferrous metals for the worm wheel and harder steel for the worm. The running of the worm gear and worm is a type of motion that transfers energy through sliding friction, thus generating a large amount of heat during the operation of the worm reducer. This causes differences in thermal expansion between the reducer's components and seals, creating gaps at the contact surfaces. Moreover, gear oil can become contaminated with water due to thermal cycling, causing it to lose its lubricating properties and potentially result in leaks.

During operation, worm gear reducers may experience temperatures beyond recommended limits as a result of friction and energy dissipation. If the temperature exceeds the allowable range, the unit should be shut down promptly, followed by an inspection of the lubrication and cooling systems. This procedure aims to quickly diagnose and address the cause of overheating in order to avoid additional damage to the reducer.

Possible causes include:

Corresponding solutions:

2.2Gearbox Noise

Gearbox noise can be troubleshooted from the following aspects:

Corresponding solutions:

2.3Abnormal Vibration

If a speed reducer exhibits unusual vibrations, it indicates a problem with internal components, such as: improperly secured transmission; worn or damaged worm gear; worn or damaged bearings; loose bolts; or foreign object intrusion.

The corresponding solutions are:

2.4Gearbox Oil Leak

Lubricating oil, a crucial component of speed reducers, plays a vital role in lubrication, sealing, and cooling. Regular oil changes ensure the speed reducer's normal operation and extend its service life.

The oil seal on the speed reducer is another essential component for its proper functioning. Wearing the oil seal will lead to oil leakage. Therefore, checking the oil seal and replacing worn seals promptly is crucial for maintaining the speed reducer's normal operation.

The speed reducer's oil sight glass, with its transparent window, allows operators to visually observe the lubricating oil level, color changes, and impurities. This helps in the timely detection of lubrication problems and prevents equipment failure. A damaged oil sight glass can also cause oil leakage. Therefore, the correct use and maintenance of the oil sight glass are essential for extending the equipment's lifespan.

Due to varying installation requirements for speed reducers in different scenarios, the required oil volume also differs. Oil should be added according to the instructions; overfilling should be avoided to prevent leakage.

If any of the above situations occur and the buyer is unable to resolve them independently, please contact a WUMA sales representative immediately. We are committed to providing our customers with high-quality service and guaranteed after-sales support, aiming to meet their needs. WUMA Transmission Co., Ltd. has extensive experience in the reducer manufacturing industry, solving problems for customers in various industries and ensuring the normal use of products.

Hot News

Hot News2026-02-24

2026-02-22

2026-02-20

2026-02-18

2026-02-16

2026-02-14